How does a blind rivet work?

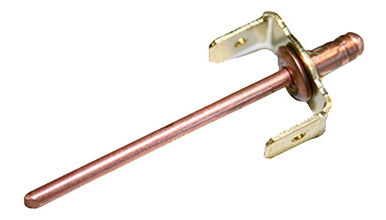

The two-piece blind rivet consists of a rivet body mounted on a mandrel.

The rivet is set from one side of the parts to be joined. After inserting the rivet into the part, the mandrel is pulled back by the tool, deforming the rivet sleeve and forming the

closing head.

The mandrel shears at a specially predetermined breaking point.