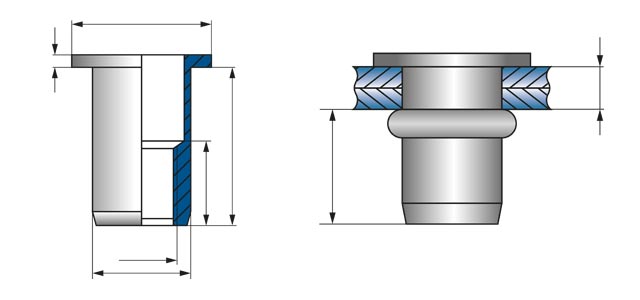

How does a blind rivet nut work?

Blind rivet nuts are characterised by very quick and simple installation.

The continous development of new types, forms and dimensions documents the nearly unlimited fields of applications. The HONSEL-Group has been one of the leading companies in this progress for decades. Blind rivet nuts have become an indispensable part modern installation engeneering.