Electric-hydraulic setting tool VNG 950

Electric-hydraulic setting tool for stationary automated or hand-held processing of blind rivet nuts and studs.

Perfect combination of high setting force, slim design and low weight. The narrow design allows a small centre distance for modular design.

- Process monitoring DMSD 2G

• Displacement encoder with resolution 0.01 mm

• Sensor technology force measurement via hydraulic pressure - Hydraulic connection for pressure intensifier

- Mechanical connection

- Tolerance compensation

• Position offset 1.5 mm

• Angular misalignment 8° - Electric motor

Monitoring of torque and rotationangle during spindle mounting and dismounting

- Hydraulic hollow piston cylinder

• stroke 12 mm

• setting force up to 58 kN - Quick-change system

• For fast handling and low-maintenance operation

• Low tool costs by using DIN screws as mandrel (option)

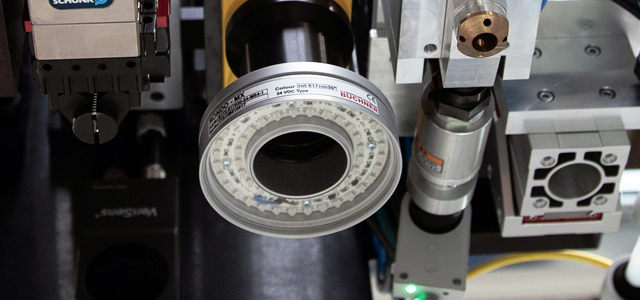

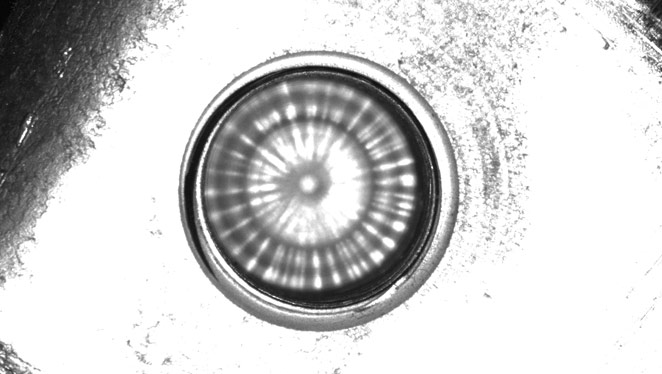

Camera technology – Position recognition

If fasteners are processed automatically, it is important for an efficient process to know the exact position of the mounting thread or mounting hole. This is the only way to optimize the process and increase the output rate.

The experts at HONSEL Automation have chosen an approach that works by means of camera technology and subsequent evaluation. If an offset in X or Y direction is detected, it can be readjusted in real time depending on the application (robot, rotary table, portal axis).

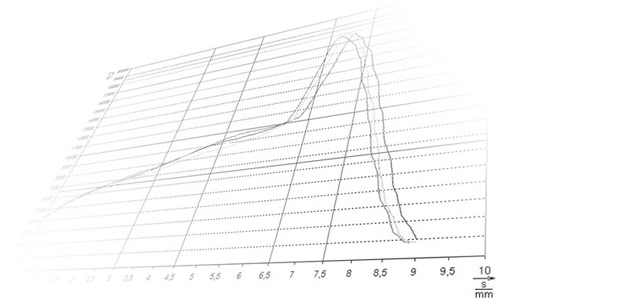

Process monitored setting

The setting process for blind rivet nuts, studs and wire threads is comparable. A fastener is threaded and led to the component. Only the speed is different. If it takes less than 1 second for a blind rivet nut to complete the process.

The VNG 950 documents setting stroke and force from each setting process.