Riwo VNG DMSD 2G

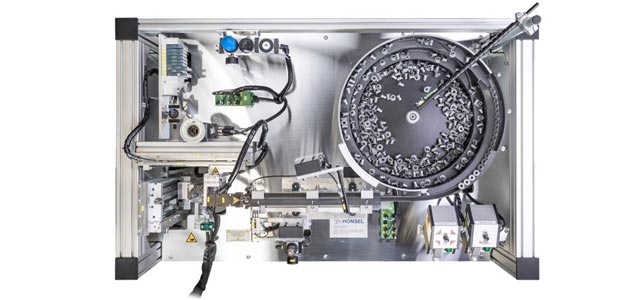

The modular Riwo VNG DMSD 2G is a fully automatic unit for setting blind rivet nuts and blind rivet studs within an automated system.

- Pneumatic / hydraulic setting unit RivSys VNG DMSD 2G

- Freely programmable electrical cantilever axis with high repeat accuracy (+/- 0.05 mm) and integrated position measuring system (+/- 0.01 mm)

- Magnetic spring unit for weight compensation

- Floating mounting of the setting unit to compensate for transverse forces during the unscrewing process

- Swivel / gripper unit for transferring the blind rivet nut or blind rivet screw to the setting unit

The Riwo VNG DMSD 2G consists either of a pneumatic-hydraulic or electro-hydraulic setting tool RivSys VNG, which is adapted to an electric linear motor with integrated position measurement. To compensate for angular tolerances of the component or when the component is provided and the resulting transverse forces during the setting process, the setting tool is mounted in a floating manner in order to counteract problems with spindling after the setting process.

The connector is transferred to the setting tool via a pneumatic rotary gripper.

Tolerances - component provision

The position of the setting hole should be within a tolerance of ± 0.2mm to the setting tool to ensure that the connector can plunge into the setting hole. The floating mounting of the setting tool ensures that if there is a pressure between the connector and the component, there are no problems with unthreading after the setting process. It should be noted that the Riwo is a stationary unit in which the setting tool is moved in the axial direction towards the component. The component provision, taking into account the component tolerances, is responsible for the fact that the setting bore is also made here.

In practice, the run-in chamfer on the connector favors the process of meeting the setting hole and plunging into the setting hole. As long as it is ensured within the component provision that this fact is achieved, the play in the front structure of the setting tool and in the adaptation of the setting tool also ensure that the connector is completely immersed in the bore.

As described, the floating mounting of the setting tool ensures that the transverse forces caused by an offset or an angular deviation of the hole during setting are compensated and can also be spindled after the setting process.

1. The blind rivet nuts are fed into a storage section via a feed device. At the end of the accumulation section, they are separated and shot through a hose and compressed air into a transfer device.

2. The transfer device consists of a pneumatic rotary gripper, via which the blind rivet nut is brought into the threading position.

3. The blind rivet nut is positioned in relation to the rotating mandrel and threaded on automatically.

4. The rotary gripper is swiveled back into the takeover position.

5. The setting tool is brought into the working position with the linear unit, the blind rivet nut plunges into the hole.

1. The blind rivet nuts are fed into a storage section via a feed device. At the end of the accumulation section, they are separated and shot through a hose and compressed air into a transfer device.

2. The transfer device consists of a pneumatic rotary gripper, via which the blind rivet nut is brought into the threading position.

3. The blind rivet nut is positioned in relation to the rotating mandrel and threaded on automatically.

4. The rotary gripper is swiveled back into the takeover position.

5. The setting tool is brought into the working position with the linear unit, the blind rivet nut plunges into the hole.

Process monitoring DMSD 2G

The setting process of a blind rivet nut is monitored with the help of the DMSD-2G process monitoring system. During the riveting process, the force curve is recorded as a function of the stroke covered by the riveting tool. After the end of the power stroke, the riveting is evaluated. The following criteria can be checked during the evaluation:

Clock cycle

For the setting of a blind rivet nut / blind rivet screw, including the automatic feeding of the blind rivet nut / blind rivet screw to the setting tool, we need approx. 5 seconds.

The cycle time is composed as follows:

- Threading the blind rivet nut = 2.5 sec.

- Setting the blind rivet nut = 2.5 sec.

(Approach the set position (200 mm travel), set, unthread and return to 0 position)

Note: The blind rivet screw is fed into the transfer system parallel to the setting process.